Factory & Equipment

With a layout perfected for efficiency, this facility is the Mother Factory of our UE Engines. Here, we can manufacture large engines with a cylinder class of 60 cm in diameter (about 25,000 hp). We are also equipped with a variety of machining facilities that allow for the precision processing of parts in all shapes and sizes.

Factory Overview

(1)Total Site Area: 52,533.68㎡

Factory Buildings: 21,474㎡

Total Floor Space: 27,313㎡

(2)Engine Test Beds : 6

(3)Maximum Operating Capacity: Approx. 18,500 kW (25,000PS)

(4)Crane Capacity: 2×200t

(5)Quayside Jib Crane for Loading and Unloading: 1×300t

Main Machinery

-

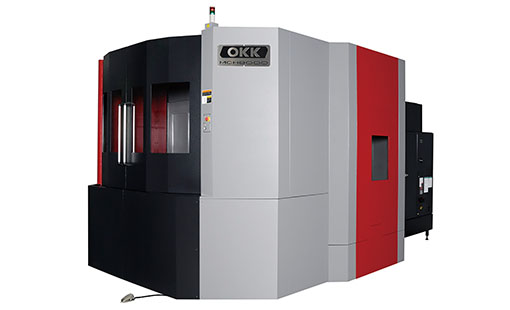

MCH8000

(box way horizontal machining center)

Manufactured Parts:Pressure-relief control valve blocks

Features:Exceptional ultra-deep cutting performance -

INTEGREXe-1550V/10Ⅱ

Equipment Name:Cylinder covers

Features:Compound turning center equipped with lathe turning and simultaneous quintaxial control function -

TU40

(NC lathe)

Manufactured Parts:Piston crowns

Features:Lathe with high maneuverability and versatility

-

MCR-A5C

(double column machining center)

Manufactured Parts:Piston heads and metallic sliding bearings

Features:5-surface processor with high precision and rigidity -

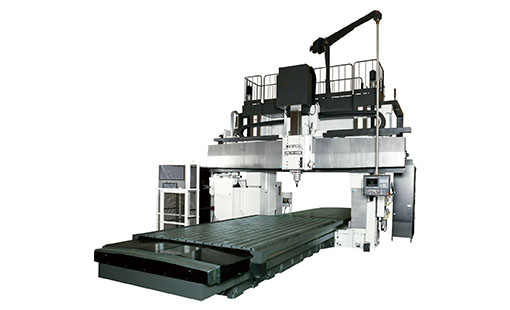

MG-45/135

(gantry plano milling machine)

Manufactured Parts:Bedplates and shield machines

Features:Large gantry miller capable of precision machining -

MCR-BⅢ

(double column machining center)

Manufactured Parts:Resin granulators

Features:Equipped with a simultaneous quintaxial control function, supports a wide range of works